Most things around us are either made of fabric or have fabric incorporated in them. Starting from the bedding, up to the clothes we wear, our furniture, and even the toys our children use, they are all made of one fabric or another. When we go to the store to purchase something, we have a basic idea of which textiles are more durable than others, but most of the time we are not sure why that is. In this article, we are going to talk about tensile strength, and we are going to let you know why it is so important when it comes to fabric.

What is it?

Let’s start with the basics and learn what tensile strength is. By definition, this is the ability of the fabric or the textile to withstand pressure or a pulling force. It means that this shows how durable the material is and what it is going to take for it to fall apart, break, or get damaged.

No matter the industry, starting from construction up to clothes manufacturing, we need to be able to measure the resistance so that we know what we can subject the material to. If we are not sure what the strength is, and if we just guess it, chances are, we are going to get it wrong at one moment or another, and we are going to either injure ourselves, or others, or we are going to provide a false description for the items that we are offering.

We need to understand how much pressure something can withstand so that we know when we can use it. Keep in mind that the tensile strength not only varies depending on the material itself, but also on the other conditions. For example, a wet fabric tends to be greater than the resistance of a dry one, but this once again varies depending on the exact textile.

When we do the measurements, we need to take different conditions into consideration, especially when it comes to textiles that are used outdoors and that can be exposed to different conditions. When constructing outdoor furniture, we need to be aware of what it can withstand after being left in the sun, what will happen if it gets wet, and what it needs to get to the breaking point.

Keep in mind that here we are not talking about what the fabric can withstand and if it is going to get damaged if it gets punctured or if sudden force is applied to it, we are just measuring how much resistance it is going to present when it is pulled in different directions. To explain it with an example, we are not measuring if the textile is going to break if it is punctured with a knife or scissors, we are just measuring if it is going to get damaged if we put something on it, if someone sits on it, or if we can use it to transport different construction materials.

More often than not, we need the elasticity of the materials and the ability to twist and turn them without them getting damaged, and because of that, gurneys and other similar items are made of textile and not something that is going to keep the same shape at all times.

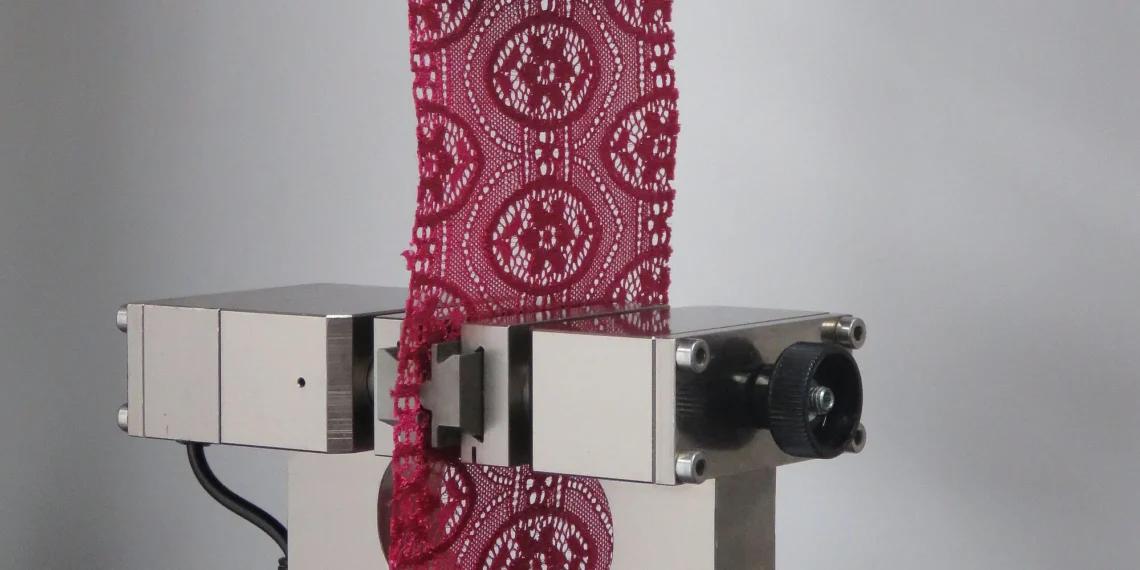

All of these measurements are done using special equipment, and according to testextextile, you can use the devices to test the tensile strength of fabrics including leather, plastic, paper, and so on, so that you can find the exact numbers that are going to help you with the manufacturing process.

Why is it important?

We need to have the exact data of how much resistance the textile is going to show so that we know how to manufacture and layer it. For some cloths, we can just put one thin layer, and the fabric is going to be able to withstand extreme pressure, however, for others, we would need to combine different layers and a special way of threading to be able to get the most resistant item that is going to last for a long time.

One interesting fact is that by combining different matters, we can get the best out of all worlds. When we combine one item that has amazing elasticity properties and when we put it together with fabric that has perfect tensile properties, we can end up with cloths that are going to stand the test of pressure, of time, and that is going to be easy to handle without getting damaged.

We need to understand the different properties of every type of textile so that we know how to handle it, how to manufacture it, and how to prevent different problems that may occur in the future.

When measuring the information for all different types of materials, we need to examine a lot of the mechanical properties. This does not only include the tensile strength and how much tension the item can withstand, but we need to also consider peeling, bursting, elongation, tear, and so on. We need to understand if the item can only withstand a certain weight for a short time or if it can stay intact even if there is a constant load. We need to know if the fabric is going to go back to its original shape and form after the load has been removed, or if it is going to get plastically deformed.

For example, the clothes that you are wearing, especially those made of cotton are going to show amazing elastic properties, and they are going to stretch to fit your body shape, even if the shirt is one size too small. However, once you take it off, it is going to go back to its original form, and you would need to wear it for many years until it loses that property and stays in the same shape that fits your body fully.

These mechanical properties are extremely important for manufacturing, safety, and durability, and without knowing the tensile strength we would not be able to provide quality goods that are going to stand the test of time and pressure. If you need to incorporate them in your place of business, make sure you choose the right testing device that is going to give you all the measurements at once without having to use excessive equipment to get the mechanical properties.